Lounge Chair Build #1

Materials, Tools, and Forms

[This is the first post in a lounge chair build Sunday series. Thanks for following along…]

With any build, we need to pick a starting point. I’ll add pertinent information without going overboard (hopefully).

Also, I can’t possibly mention each variable or each tool. I expound on a few tools, to explain why they are helpful (and why a few of them are optional).

Materials:

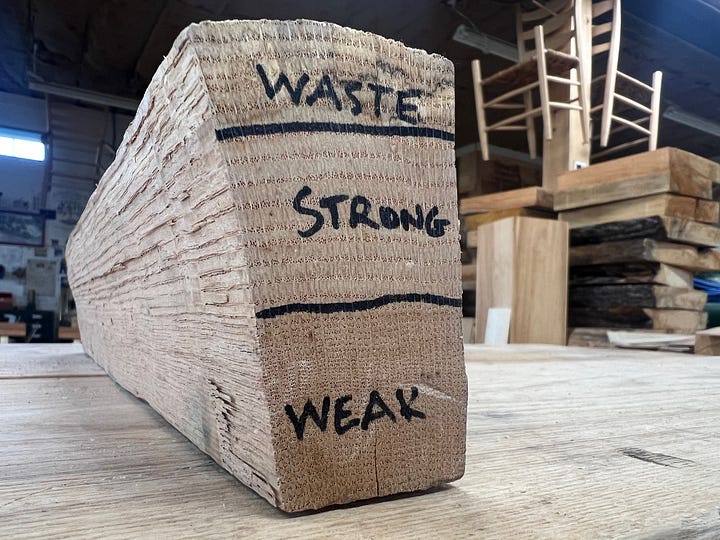

40” lengths of straight grain oak will suffice. I use northern red oak, since it’s beautiful and common to us in midcoast Maine. White oak works, as does ash and other ring-porous hardwoods.

Will soaking kiln-dried or air-dried material work for this chair? I don’t know…haven’t tried it. I see lots of success from chairmakers using dry timber to make Boggs-style Berea chairs. Those chairs have significant bends, and some of those chairmakers use cherry, maple, and walnut (woods that are more bend-fickle than fresh oak). It seems possible, but I’m ignorant to give advice here.

I frequently use a few bamboo skewers for pins. Which is unnecessary if you’d prefer making your own from scrap material. (skewers are found at the local grocer)

Recommendation: find straight-grained, clear material. It’ll make life easier. Avoid material with knots, with curly figure, and anything that’s been sitting on the ground for a long time (Logs/material that sits for long stretches under the sun and on the wet ground is a wildcard. Could be good…could be filled with checks and starting to rot…could be brash but show no visible signs. Best to avoid these logs).

I use green materials for everything except the arms. For those, I use straight-grain rift or quartersawn 6/4 red oak. Due to the drying time needed to fully cure these parts, it’s advantageous to start with dry material.

Weaving options: hickory bark, Shaker tape, or flat reed (among others).

Tools:

The following are recommended hand tools for the chair build. We’ll use a few more (power drills, for example), but this is the primary set of tools during the chair construction. I’ve added a few notes on certain tools below.

Drawknife

Spokeshave

Bevel gauge(s)

Block plane

Framing Square

Tape measure

Combination square

Card scraper(s)

Hand saw/Crosscut saw

Flush cut saw

Claw hammer

Dead Blow hammer or small sledge hammer

Chisels (¼” and 1”)

Utility knife

Drill bits (5/8” for mortises). More on drill bits below.

I use the 5/8” power tenon cutter from Lee Valley. It’s not necessary. Tenons can be made with a hollow auger/brace, or shaping them by hand.

Splitting tools: Wedges, sledge hammer, hatchet, small axe, froe, and brake.

Keep reading with a 7-day free trial

Subscribe to With Working Hands to keep reading this post and get 7 days of free access to the full post archives.